The development of a

portable DC pump oil-free compressor nebulizer involves the integration of various technologies and engineering principles to create a compact, efficient, and user-friendly medical device. The process typically includes the following stages:

Research and Conceptualization: Engineers and medical professionals collaborate to identify the need for a portable nebulizer and the specific requirements it must meet. They study existing nebulizer technologies and assess the advantages and limitations of oil-free compressor designs. The team also considers factors like power source, noise level, portability, and ease of use.

Design and Prototyping: Based on the research findings, the team develops initial designs and prototypes. These prototypes may be used for testing and evaluation by both medical professionals and potential users. Feedback from these evaluations helps refine the design.

Compressor Technology: Developing an oil-free compressor is a critical aspect of the design. Oil-free compressors typically use specialized materials and design features to eliminate the need for lubricating oil, reducing maintenance and the risk of oil contamination.

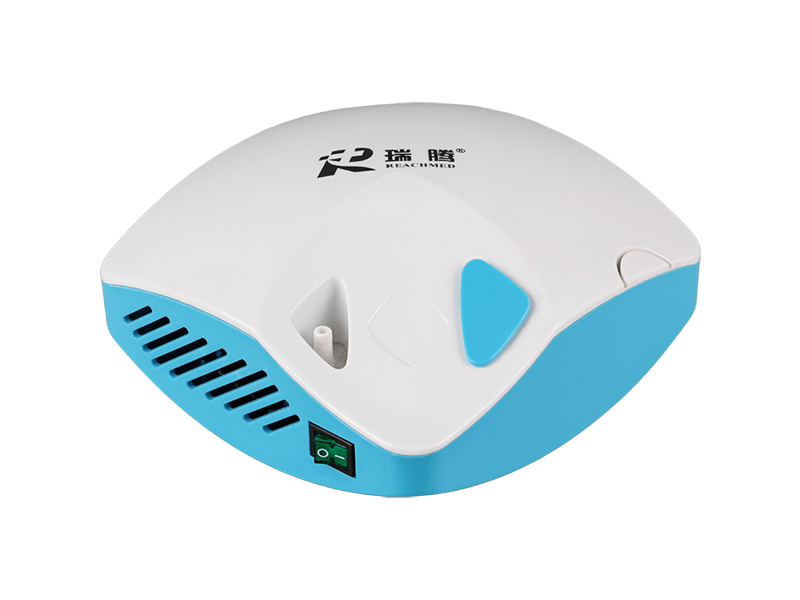

Miniaturization and Portability: One of the main challenges is miniaturizing the components without compromising performance. This involves engineering solutions to reduce the size and weight of the compressor, electronic controls, and power source.

Battery and Power Management: For portability, the nebulizer needs a reliable and rechargeable power source. Engineers work on optimizing battery technology, power management circuits, and efficiency to ensure long battery life and convenient charging.

Nebulization Technology: Selecting the appropriate nebulization technology is crucial. Jet nebulizers are commonly used due to their reliability and simplicity. Ultrasonic and mesh nebulizers are also possible options, each with its advantages and challenges.

Electronic Control System: The nebulizer requires an electronic control system to manage the operation of the compressor, adjust airflow, and control the nebulization process. The control system may include user interfaces like buttons or touchscreens for ease of operation.

Safety and Quality Assurance: Ensuring the safety and reliability of the device is a paramount concern. The nebulizer must meet medical device regulations and undergo rigorous testing to verify its performance and safety.

Manufacturing and Production: Once the design is finalized and tested, the nebulizer enters the manufacturing phase. Specialized production processes and quality control are implemented to ensure consistency and reliability in mass production.

Regulatory Approval: Before the nebulizer can be marketed and sold, it must undergo regulatory approval from relevant health authorities. This process ensures that the device meets specific safety and performance standards.

Throughout the development process, collaboration between engineers, medical professionals, and regulatory experts is essential to create a portable DC pump oil-free compressor nebulizer that meets the needs of patients, is easy to use, and complies with medical device regulations.